Zinc Alloy Diecast Process for Medals Challenge Coins

DIE CASTING For medals, Challenge coins.

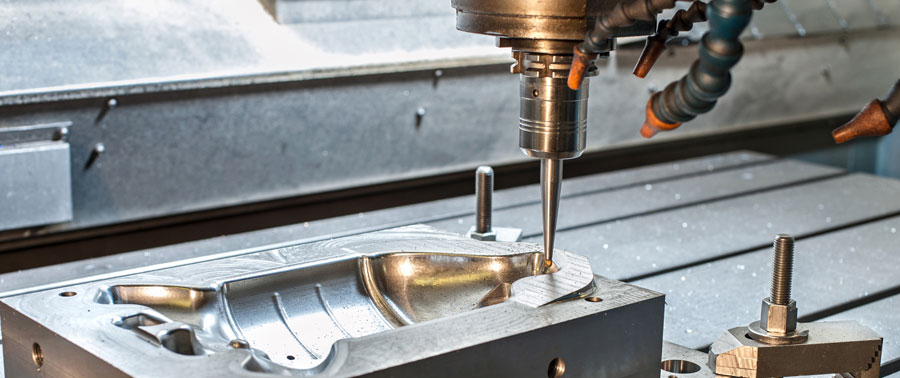

Die spreading is a production procedure in which liquified metal is poured or pushed into steel molds. The mold and mildews-- likewise called devices or dies-- are developed utilizing steel and are specially made for each Personalized medals. This allows each part to be created with accuracy and also repeatability. Zinc Alloy are the most typically used die spreading Medals, or Challenge coins. Most of them made in Dingying Equipment.

Die Spreading Advantages for Medals, Coins.

Die casting can have substantial benefits over other producing processes, which often lead to significant price savings, not just in the part Medal or coins price itself yet additionally in the general expense of Medal or coins production. When you cast a Medal or coins, you can produce intricate web forms, including outside threads and intricate interior features with very little draft angles-- lessening second operations. You can likewise integrate several components right into a single part to be one entire medals or coins, eliminating setting up procedures as well as reducing labor prices, with the included benefits of simplified stock control as well as greater element uniformity.

Various other advantages include:.

Variable wall surface densities.

Tighter resistances.

Fewer actions from resources to end up part.

Quick production cycle times.

Decrease in product scrap.

Long tool life, especially for zinc alloy.

Die Casting Alloys.

Zinc alloy are the major die casting alloys to making the medals or coins, also other metal crafts, They are usually non-ferrous as well as their mechanical homes vary significantly to fit almost every type of application a maker might need. Not only can die cast alloys stand up to high operating temperature levels, however they are additionally completely recyclable. Die cast alloys also have:.

Die casting zinc, die casting aluminum, die casting magnesium.

Good rust resistance.

High stamina and also firmness.

High thermal conductivity.

High electrical conductivity.

Exceptional EMI/RFI shielding homes.

Great ending up attributes.

Separately, each die cast alloy uses a selection of benefits that the other may not provide. That is among the excellent aspects of die casting, you do not need to be restricted when it pertains to selecting the appropriate steel.

Die Cast Process.

There isn't one single process that can suit every medals or coins. Each Medal is different which is why We offers multiple remedies for all die casting needs. This guarantees the right process is constantly made use of for the best application. At Dynacast, we offerthe hot chamber kinds of die casting processes.

Hot-Chamber.

Used for zinc alloys hot-chamber die spreading is a wonderful alternative for alloys that do not conveniently assault and also erode metal pots, cylinders, and bettors. Currently, to make the customized medals, or coins, We commonly choose Warm chamber type.

Injected Metal Assembly.

Since 2009, one-step production option, Injected Steel Setting up is typically utilized for medals or other steel crafts signing up with as well as setting up manufacturing and decreases production expenses.

Net form very first time.

Eliminates second procedures like assembly and machining.

Complex geometry as well as limited tolerances at higher speeds.

Minimum part-to-part variation compared to standard multi-cavity dies.

Small tooling that is much less vulnerable to parting-line variant and also its adverse effect on the finished part's dimensional tolerances.

English

English Español

Español Français

Français Deutsch

Deutsch Русский

Русский Português

Português 日本語

日本語

Customized Award Medals

Customized Award Medals Commemorative Challenge Coins

Commemorative Challenge Coins Enamel Lapel Pins

Enamel Lapel Pins Army Cap badge military Hat Badge

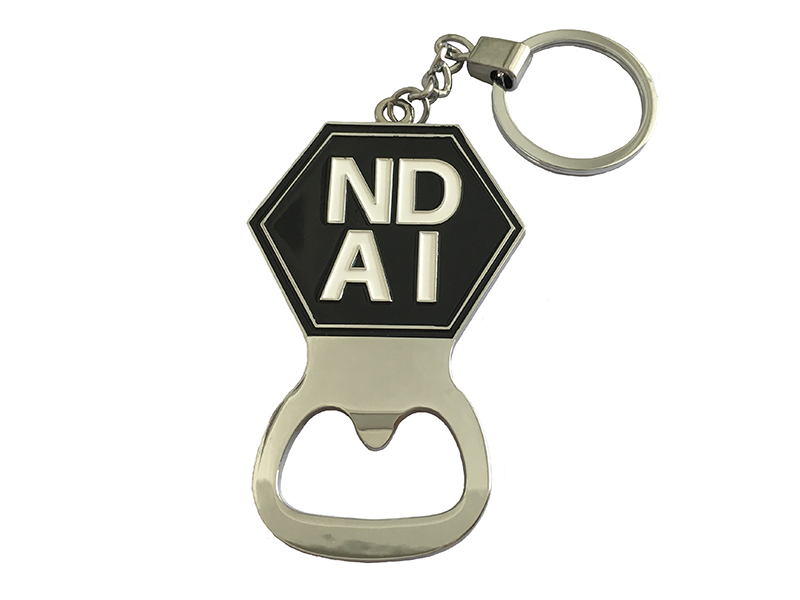

Army Cap badge military Hat Badge Custom Enamel Metal Keychains

Custom Enamel Metal Keychains Bottle Openers and Red Wine Corkscrews

Bottle Openers and Red Wine Corkscrews Souvenir Police badge

Souvenir Police badge Military Badges

Military Badges Army Medals & Medallions

Army Medals & Medallions Cufflinks/ Tie Pubs/ Tie Tacks

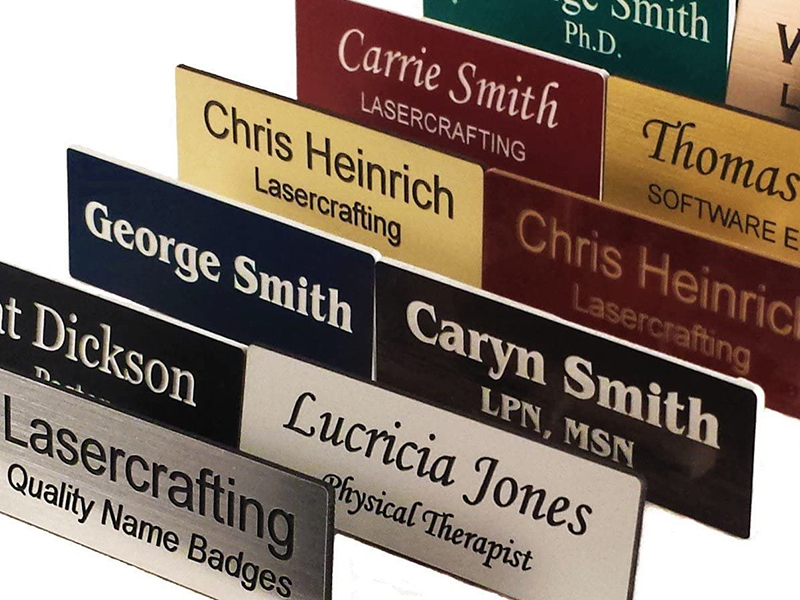

Cufflinks/ Tie Pubs/ Tie Tacks Name tag, Dog Tag,Pet Tag

Name tag, Dog Tag,Pet Tag Pewter Ornametal

Pewter Ornametal